Paper on the identification of pottery forming based on statistical surface analysis was published in the Archaeological and Anthropological Science.

Abstract:

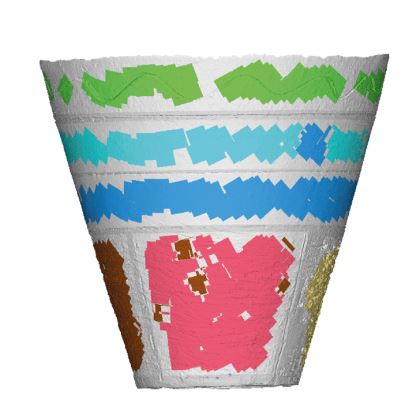

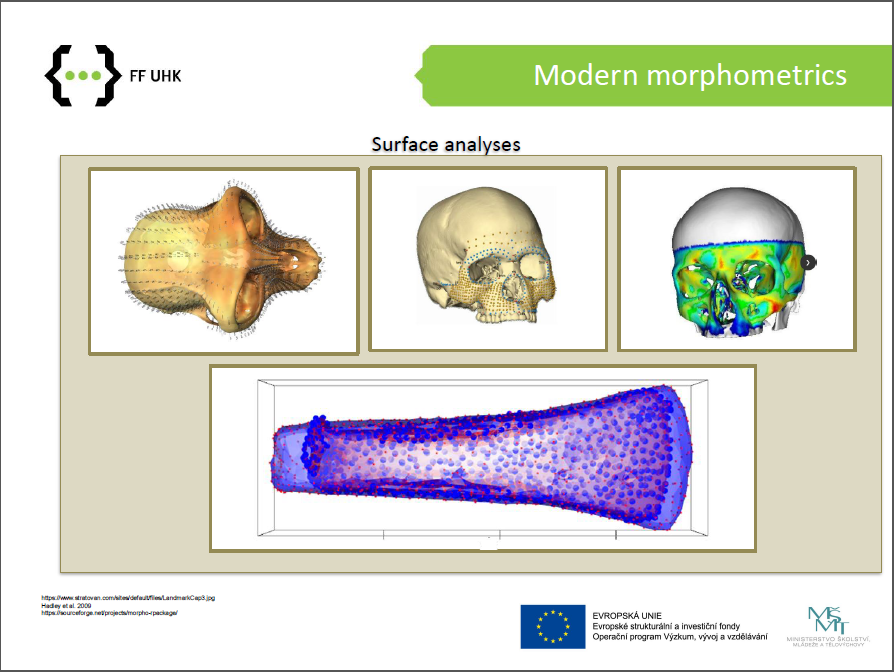

This article explores the possibilities of distinguishing different pottery forming methods utilising rotational movement based on a statistical analysis of the surface topography and variations in wall thickness. The presented topographic analysis is based on calculation of the surface regularity that is approached as measurement of the difference between the 3D representation of the pottery surface and the corresponding ideal vessel shape, obtained by rotating a model profile around the rotational axis. These differences are expressed using basic surface roughness parameters. In addition, analysis of wall thickness variability and the overall shape of the horizontal sections using elliptic Fourier analysis (EFA) were performed. The study was based on a pilot experimental dataset of vessels made using three forming methods: coiling in combination with wheel finishing employed using a turntable and using a potter’s wheel and wheel throwing. The results show that, with an increasing contribution of rotational movement in the forming sequence, a gradual increase in the regularity of vessel shapes and a decrease in wall thickness variability are observed. The differences in these two parameters allow us to distinguish among the studied forming methods. Automatic classification using elliptic Fourier analysis and support vector machine (SVM) indicates reliable classification for the lower parts of the experimental vessels.

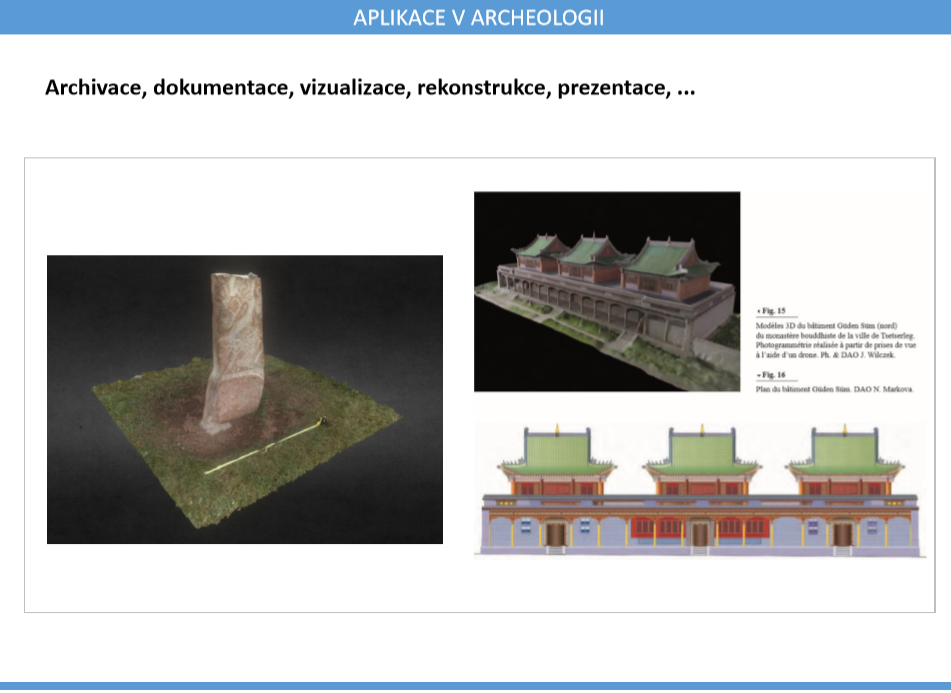

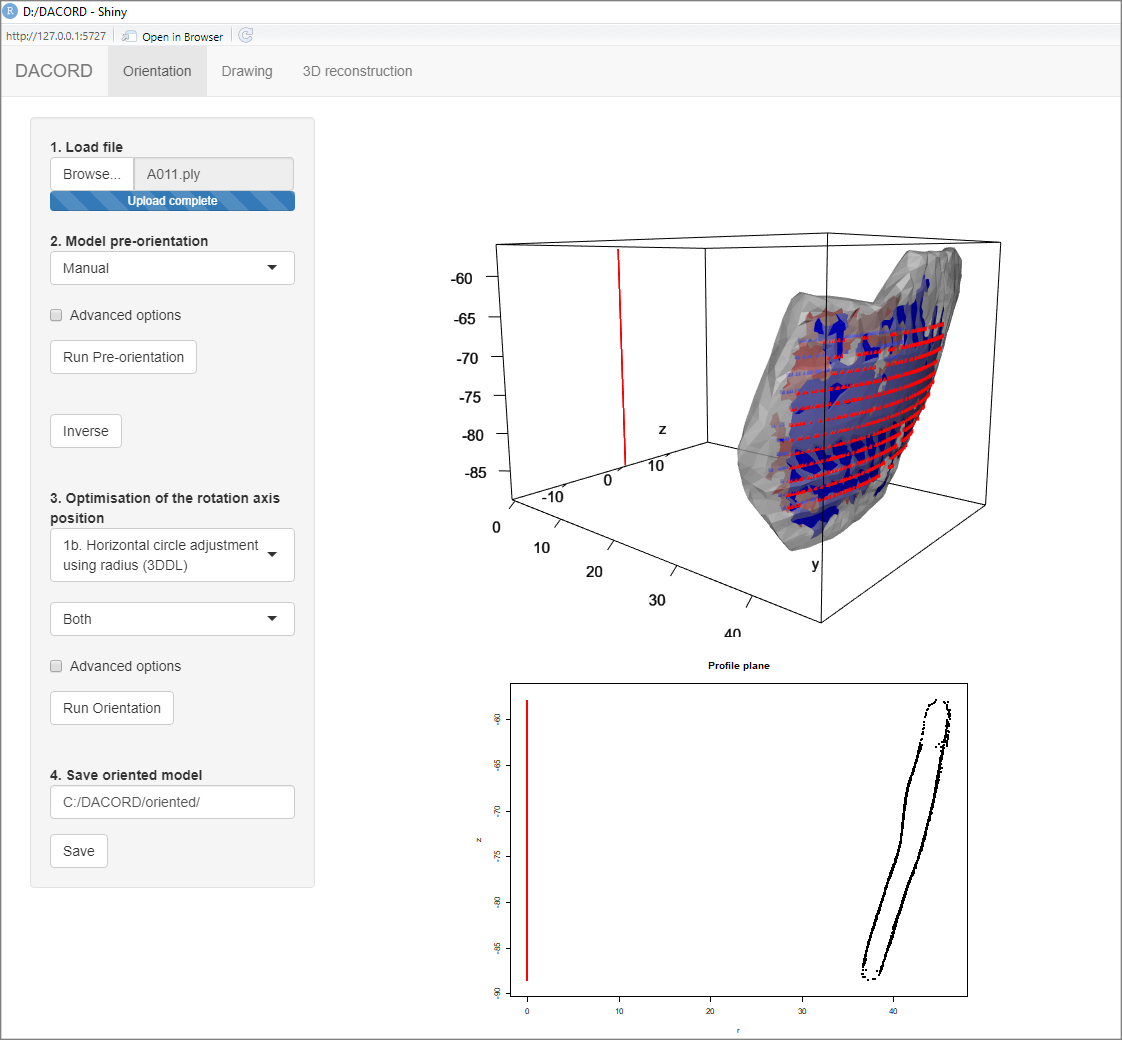

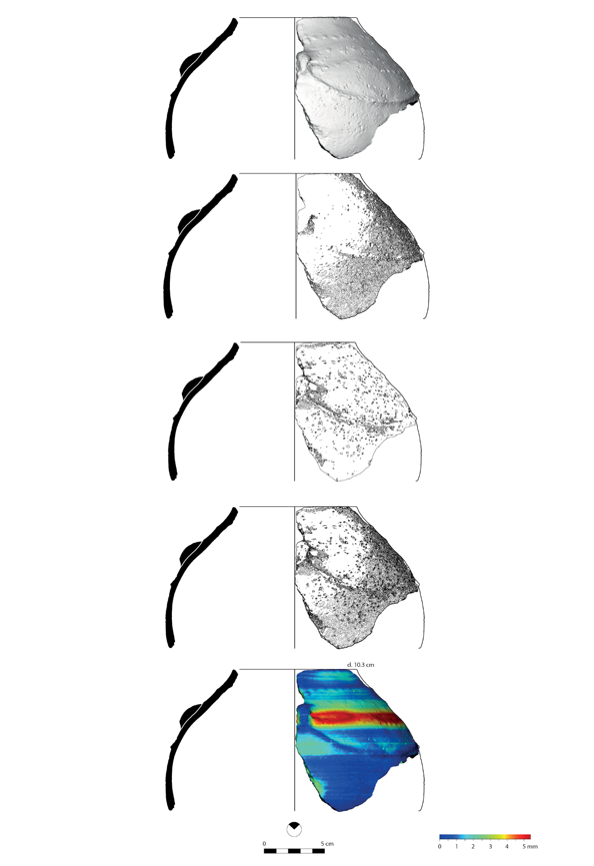

Archaeologists spend considerable time orienting and drawing ceramic fragments by hand for documentation, to infer their manufacture, the nature of the discovery site and its chronology, and to develop hypotheses about commercial and cultural exchanges, social organisation, resource exploitation, and taphonomic processes. This study presents a survey of existing solutions to the time-consuming problem of orienting and drawing pottery fragments. Orientation is based on the 3D geometry of pottery models, which can now be acquired in minutes with low-cost 3D scanners. Several methods are presented: they are based on normal vectors, or circle fittings, or profile fittings. All these methods seek to determine the optimal position of the rotation axis. We also present and discuss new approaches and improvements to existing methods. We have developed a suite of functions for the computer-assisted orientation and drawing of archaeological pottery. The profile and contours of the fragment, as well as any possible decoration, can be depicted in various ways: photorealistic rendering or dotted patterns, calculated by ambient occlusion, combined or not with artificial light. The general workflow, evaluated using both synthetic and real-world fragments, is rapid, accurate, and reproducible. It drastically reduces the amount of routine work required to document ceramic artefacts. The information produced, together with the 3D representation of the fragments, can easily be archived and/or exchanged within the archaeological community for further research. The source code (built in the R environment), together with an installation notice and examples, is freely downloadable.

Archaeologists spend considerable time orienting and drawing ceramic fragments by hand for documentation, to infer their manufacture, the nature of the discovery site and its chronology, and to develop hypotheses about commercial and cultural exchanges, social organisation, resource exploitation, and taphonomic processes. This study presents a survey of existing solutions to the time-consuming problem of orienting and drawing pottery fragments. Orientation is based on the 3D geometry of pottery models, which can now be acquired in minutes with low-cost 3D scanners. Several methods are presented: they are based on normal vectors, or circle fittings, or profile fittings. All these methods seek to determine the optimal position of the rotation axis. We also present and discuss new approaches and improvements to existing methods. We have developed a suite of functions for the computer-assisted orientation and drawing of archaeological pottery. The profile and contours of the fragment, as well as any possible decoration, can be depicted in various ways: photorealistic rendering or dotted patterns, calculated by ambient occlusion, combined or not with artificial light. The general workflow, evaluated using both synthetic and real-world fragments, is rapid, accurate, and reproducible. It drastically reduces the amount of routine work required to document ceramic artefacts. The information produced, together with the 3D representation of the fragments, can easily be archived and/or exchanged within the archaeological community for further research. The source code (built in the R environment), together with an installation notice and examples, is freely downloadable.